In manufacturing companies, theses costs usually consist of direct materials, direct labor, and manufacturing overhead cost. Indirect allocation requires careful consideration of allocation bases to ensure that costs are allocated fairly and accurately. Common methods of indirect allocation include the use of predetermined overhead rates or activity-based costing (ABC) systems.

- Let’s say you’re considering hiring more staff to handle the increasing number of orders.

- Additionally, the formulation assists in streamlining processes by aligning expenses with the company's financial objectives.

- A common mistake in calculating total period costs is misclassifying product costs as period costs.

- Also known as product costs, inventoriable costs differ hugely, depending on various factors, including the type of industry it is being applied in, the supplier it is passing through, etc.

- Period costs immediately expense themselves, appearing on the income statement for the specific period they occurred.

- Period costs are a subset of operating costs, specifically those expenses that are expensed in the current accounting period.

How To Create Accurate Cash Flow Projections

- Period costs are expenses that aren't directly tied to production, and they're incurred during an accounting period regardless of the volume of goods produced or sold.

- Once you identify the indirect costs, you must choose an allocation method to distribute these costs to products.

- Such cost classifications have been proven useful to people, like most analysts who develop several costs, classifying them per their uses in various managerial applications.

- Change in cost is calculating by deducting original production cost with new production costs.

- Analyzing Period Costs enables management to evaluate the performance of different departments and identify areas for improvement.

Current expenses directly affect the current financial period. Understanding these differences is important for performing a detailed financial analysis. This makes it hard to know the exact cost of manufacturing a product now. They have already been incurred or spent and are separate from current decision-making processes. A cost management system can integrate seamlessly with other business tools such as ERP, accounting software, and supply chain management systems. This allows for streamlined data flow between departments, improving overall efficiency.

Details of calculating total period cost in accounting and provide you with valuable insights.

At LedgerFi, we help businesses track payroll expenses, ensure compliance, and optimize payroll spending to maximize profits. A business making $1 million in revenue should budget payroll based on industry standards to maintain profitability. The variable costing calculator can be used by following the steps as discussed below. Markets change, material costs fluctuate, and new technologies pop up all the time. The key is staying flexible and regularly reviewing your costs to make sure you're on the right track.

Product Costs vs Period Costs: A Guide to Costs of Product

Adding more labor to a fixed capital cost reduces the marginal cost of labor. The total fixed cost is calculated over a short period like a month or six months. The costs of production are always a factor that businesses want to perfect as this factor ultimately decides profitability and their overall growth in the market. Both variable and absorption are factors that are often misunderstood for one another.

Period costs are of no less help, as they allow you to understand how well you’re running your business. In his role, John oversees the tracking & forecasting of KPIs across all business segments in the organization to drive insights for the objective of operational excellence and growth. He is passionate how to find total period cost about empowering key stakeholders at Cin7 to achieve more today than they could yesterday. John brings over 10 years of career experience across various operational and data analytics roles. Learn how Cin7’s all-in-one inventory management software can help your business. Discover how the right financial reporting software can boost your practice.

Manufacturing Overhead: The Silent Cost Eater

Fixed costs remain the same over a specific period, regardless of production levels, while variable costs fluctuate with the production level. Period costs may include both fixed and variable elements, such as rent (fixed) and sales commissions (variable). Once you identify the indirect costs, you must choose an allocation method to distribute these costs to products. Machine hours measure how much machine time is used for production, while labor hours focus on the time employees spend in production.

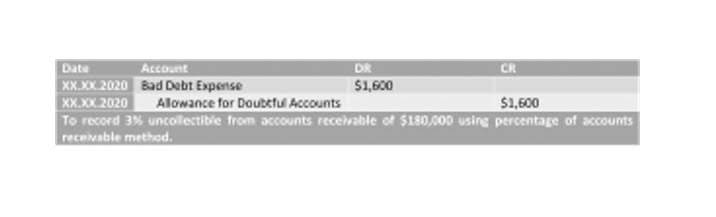

How to Calculate Total Period Cost

Variable cost or unit-level cost is a method of cost accounting which accounts the costs of production directly vary with the output. Fixed manufacturing costs are not considered for variable costing accounting. Before delving into total period cost calculation, it’s important to distinguish between direct and indirect costs. Variable costing poorly upholds the matching principle, as related expenses are not recognized in the same period as related revenue. Bookkeeping vs. Accounting In our example above, under variable costing, we would expense all fixed manufacturing overhead in the period occurred. The period cost is important and a necessary thing to keep track of because it allows you to know your company’s net income for each accounting period.

However, in cases where all materials are used, the COGM and total manufacturing cost would be the same. Direct costs change based on the production period and how much product you manufacture. This generally includes materials and labor, which vary based on many factors, such as demand planning and staffing.Wondering how to calculate direct materials cost? Direct materials are calculated by subtracting the direct materials left at the end of the production period from the total amount of materials you started with and purchased in the period. To calculate the total period cost, you need to identify various cost elements that contribute to the overall expenses during a specific accounting period.

- Keeping a close tab on this metric carries a lot of utility.

- Managing your CAC Payback Period effectively requires strategic insight and reliable financial data.

- Finally, multiply the quantity of each raw material by its cost per unit.

- The total manufacturing cost formula is among many tools that can help improve efficiencies, reduce costs, and boost productivity.

- Of course, there are several advantages to using the total cost formula.

Variable costs change according to the volume of goods or services being produced. Fixed costs are independent of the number of goods being produced. It depends on factors like the costs of the alternative chosen and the benefits. Raw materials, labor, and commissions might be few examples of the costs incurred by an organization. It is the contrary scenario from fixed costs where, those costs would be incurred irrespective of the CARES Act output of the organization.